After completing an engineering assessment on a heavy vehicle overpass, load restrictions were enforced on the bridge to limit the passage of vehicle that are at high risk of damaging the structure. After enforcement of the load restrictions, it was suspected that overweight vehicles were still utilising the overpass without authorisation, posing an asset integrity risk to drivers and the asset owner.

The asset owner engaged Rockfield to provide an overloaded vehicle monitoring system to capture information on vehicles exceeding their permitted weight limits.

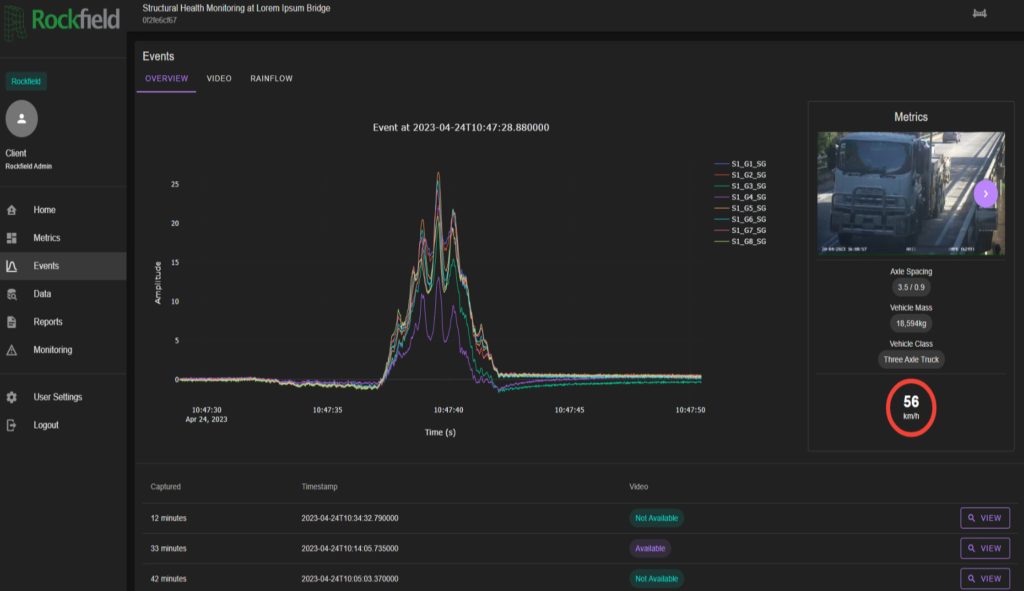

To avoid installation of a costly weigh in motion system within the bridge deck, Rockfield proposed a contactless overloaded vehicle monitoring solution using strain gauges on the underside of bridge girders. 16 high precision strain gauges were installed via epoxy bonding to avoid drilling into the pre-stressed units, and live vehicle traffic loads were captured and transmitted to an online dashboard service. An automatic number plate recognition (ANPR) camera was also commissioned and installed to provide confirmation of the overloaded vehicles and allow identification.

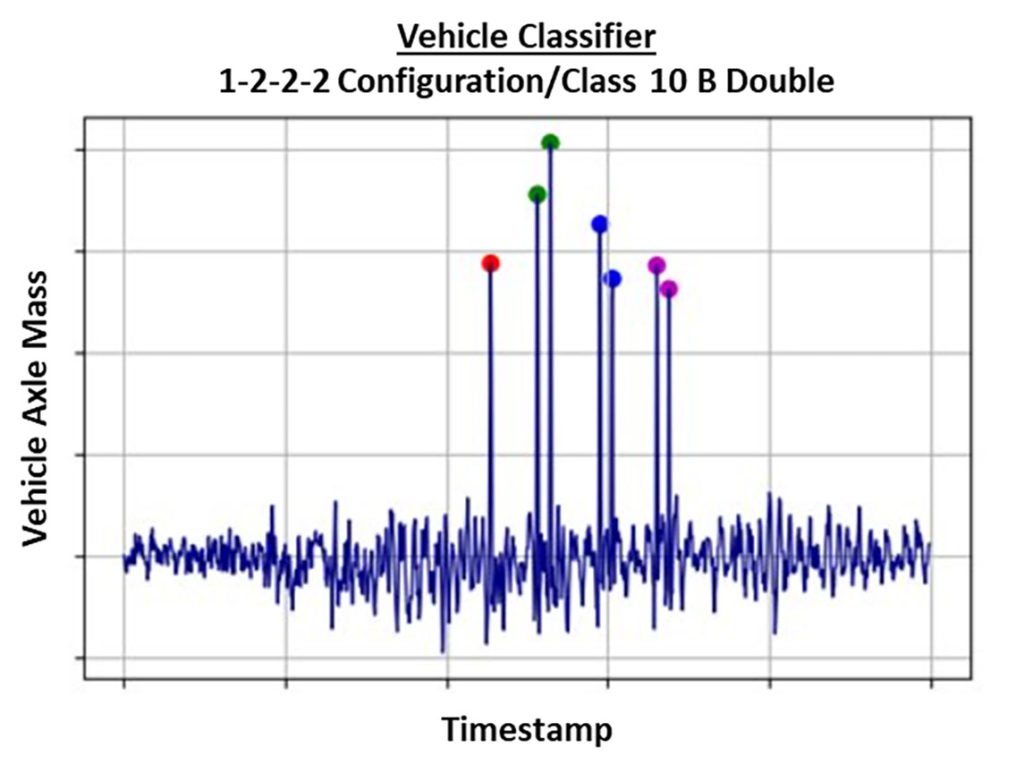

To calibrate the monitoring system, a series of load tests were conducted using a vehicle of known axle mass. The load testing provided a reference range for normal and abnormal vehicle load conditions, allowing Rockfield’s cloud platform to isolate and detect any potentially abnormal and overloaded vehicles. Alongside the strain data, vehicle speeds were calculated and provided to the client.