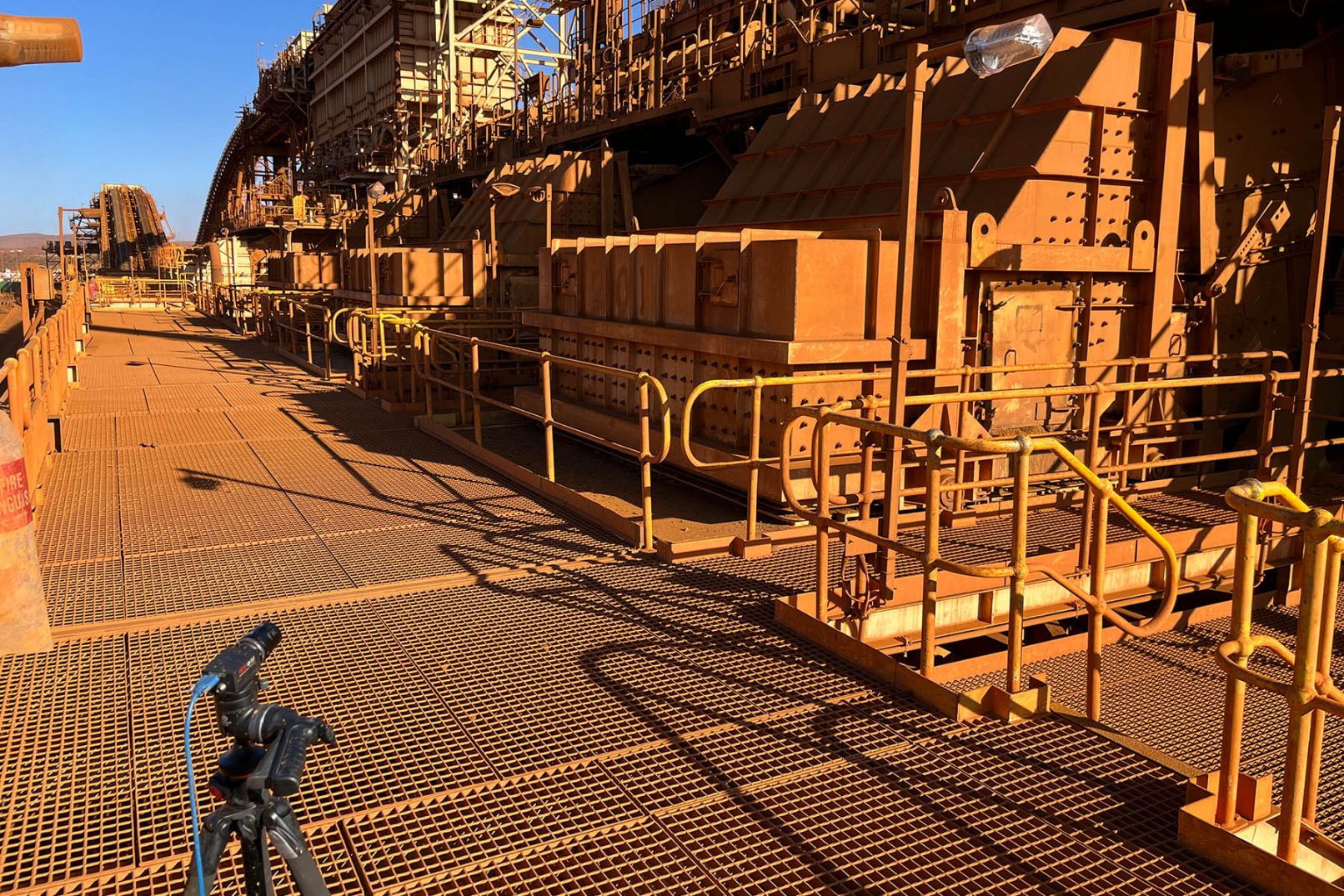

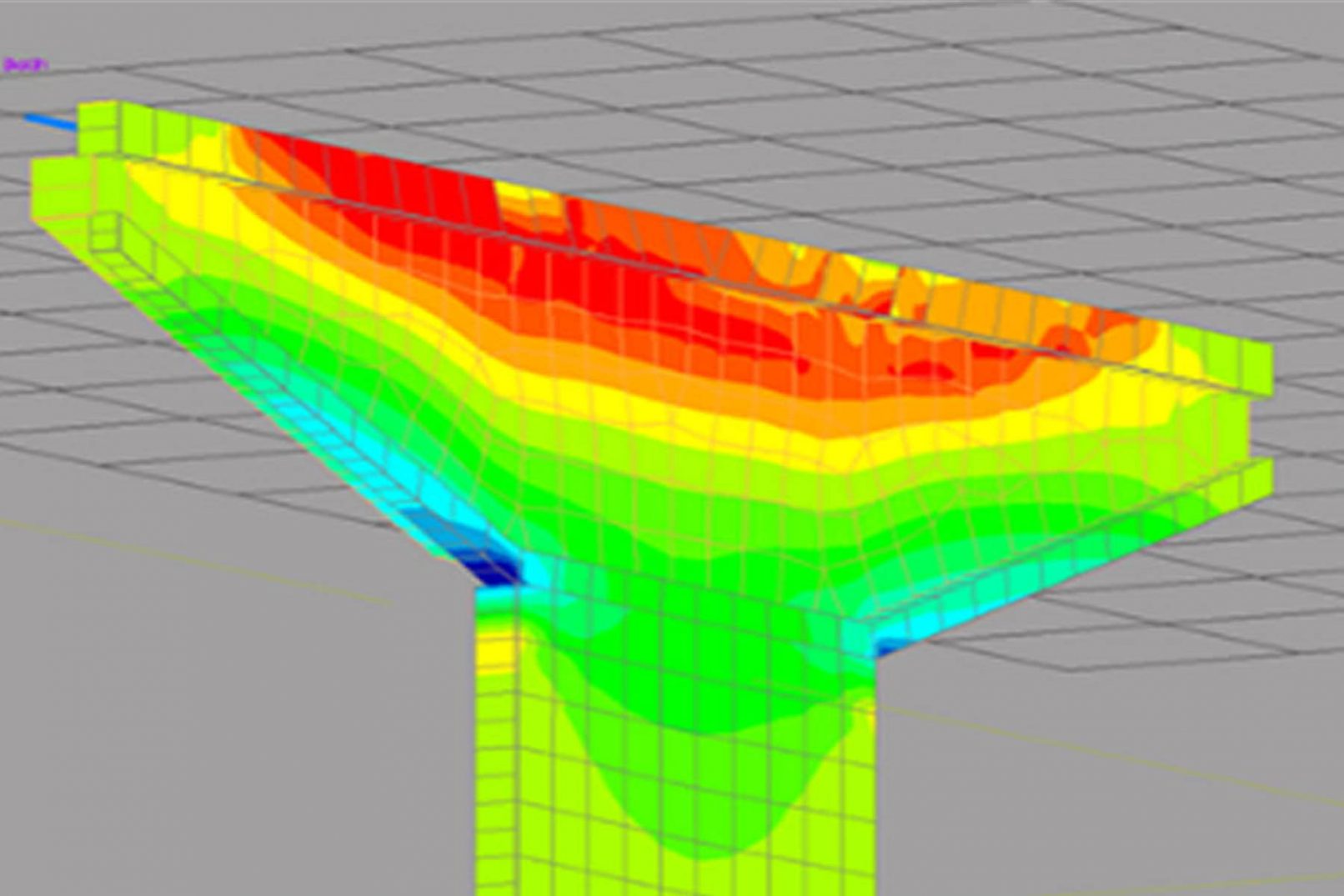

Whether it be to validate generalist engineering approaches that can often be conservative or inadequate, or to extract data from unknown systems for diagnostic activities; field instrumentation, measurement and testing protocols can be hugely effective in gaining a complete picture of a problem. Asset owners require realistic and accurate information about their infrastructure, field measurement and testing activities.

Instrumentation, Measurement and Testing

Inform key asset management decisions by understanding the facts

Our point of difference:

Rockfield has extensive experience with agnostic systems comprising sensors, data acquisition equipment, communications, cloud stack and visualisation technologies. For over a combined total of 50 years, we have helped organisations through designing, procuring, assembling, commissioning and maintaining instrumentation systems. Our multi-disciplinary domain expertise in engineering design and investigations allows us to effectively develop infrastructure and plant testing programs and assist asset owners optimise asset performance throughout all phases of the lifecycle.

What we can deliver:

-

- Design through to commissioning and on-going monitoring and maintenance of data acquisition systems for mining, rail, process, export and public infrastructure/plant

- Motion amplification condition monitoring site services

- Customised load cell pin/component design and manufacture

- Infrastructure performance, load case and design verification and testing

- Heavy haul and passenger rail car structural and dynamics performance measurement and testing/monitoring

- Mining and heavy industry mobile plant and balance/stockyard machines structural/dynamics performance measurement and testing/monitoring

- Australian Standards compliance commissioning measurements

- Reservoir external and internal/submerged structural performance monitoring

Speak to one of our experts today

Daniel Whipp

InfraTech Lead | Senior Software Engineer

Daniel Stephenson

Engineering Manager | Associate Technical Director | Structures

Chris Coulson

Associate Technical Director | Mechanical

William Milne

Asset Management Lead | Principal Engineer